Fix hole in PDRacer sailboat with fiberglass and epoxy

Boats built from plywood are very durable boats, and they are super easy to repair. Personally I prefer to use 3/8" plywood on the bottom of my PDRacer because it is so tough, but there are circumstances that you can break it.

I was out on a nice day, and all of a sudden mother nature reared her ugly side and whipped the wind up to 50 mph. The waves picked up and I decided to make a run for shore, to wait out the bad weather. Unfortunately the only spot I could goto was a rocky shore, and I landed on a pointy rock which punched this hole in my hull. After the wind died, it wasn't much of a big deal to repair it, I simply stuffed a rag in the hole to plug it up and got home just fine.

Damage and holes are fairly easy to repair, especially if you have some epoxy and a little fiberglass laying around. This is one method for repairing a hole.

Here is a look at the outside of the hole after I sanded it down a bit. As you can see, there is a slight problem, if I apply epoxy or filler it will just drop right through the hole. The other side of that hole is inside the airbox and kinda tough to reach.

On the inside of the airbox, I reached in and pulled off as many splinters as I could, the hole was just barely within my reach.

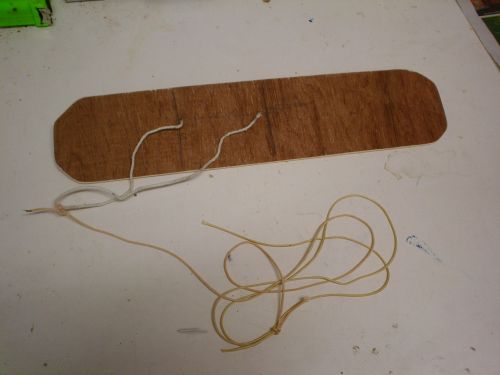

I decided to make a backup board to stick in there. To hold it in place, I added a string so I could pull on it from the outside.

I applied lots of glue.

I fished the line though the hole, then used a screw driver twisted in the line to make it tight and apply pressure. This holds backup board to the hull in compression to help the glue cure.

The technique is called a Spanish Windlass, and it in the old days they used the technique to winch things around. Egyptians also used this technique to lift heavy stones.

Presto the backing plate is plugging the hole, and I I simply clipped off the line.

Then I repaired the outside of the hull just like any other fiberglass repair project.